Optical Apparatus Renewal, Bourbaki Panorama, Lucerne

Project overview

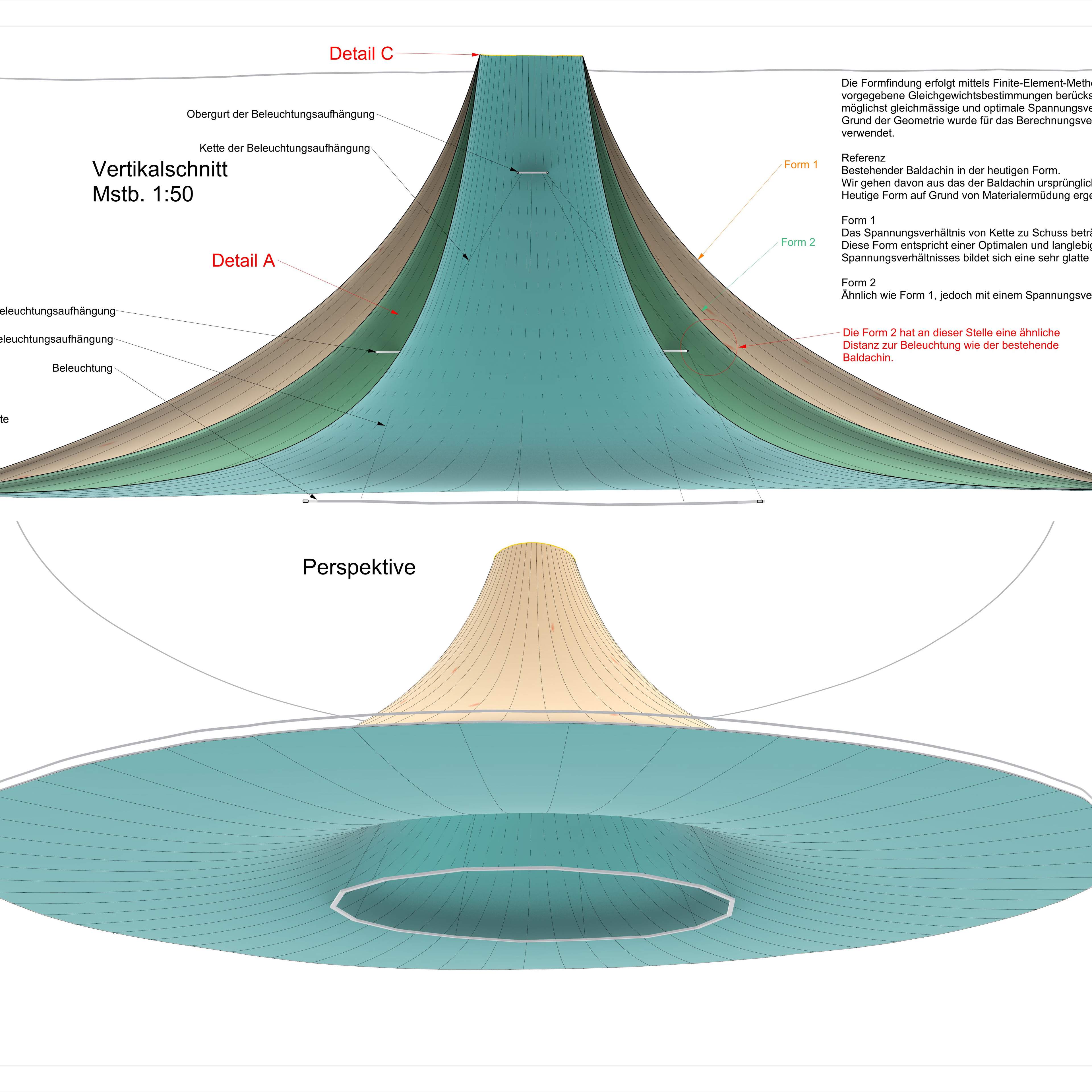

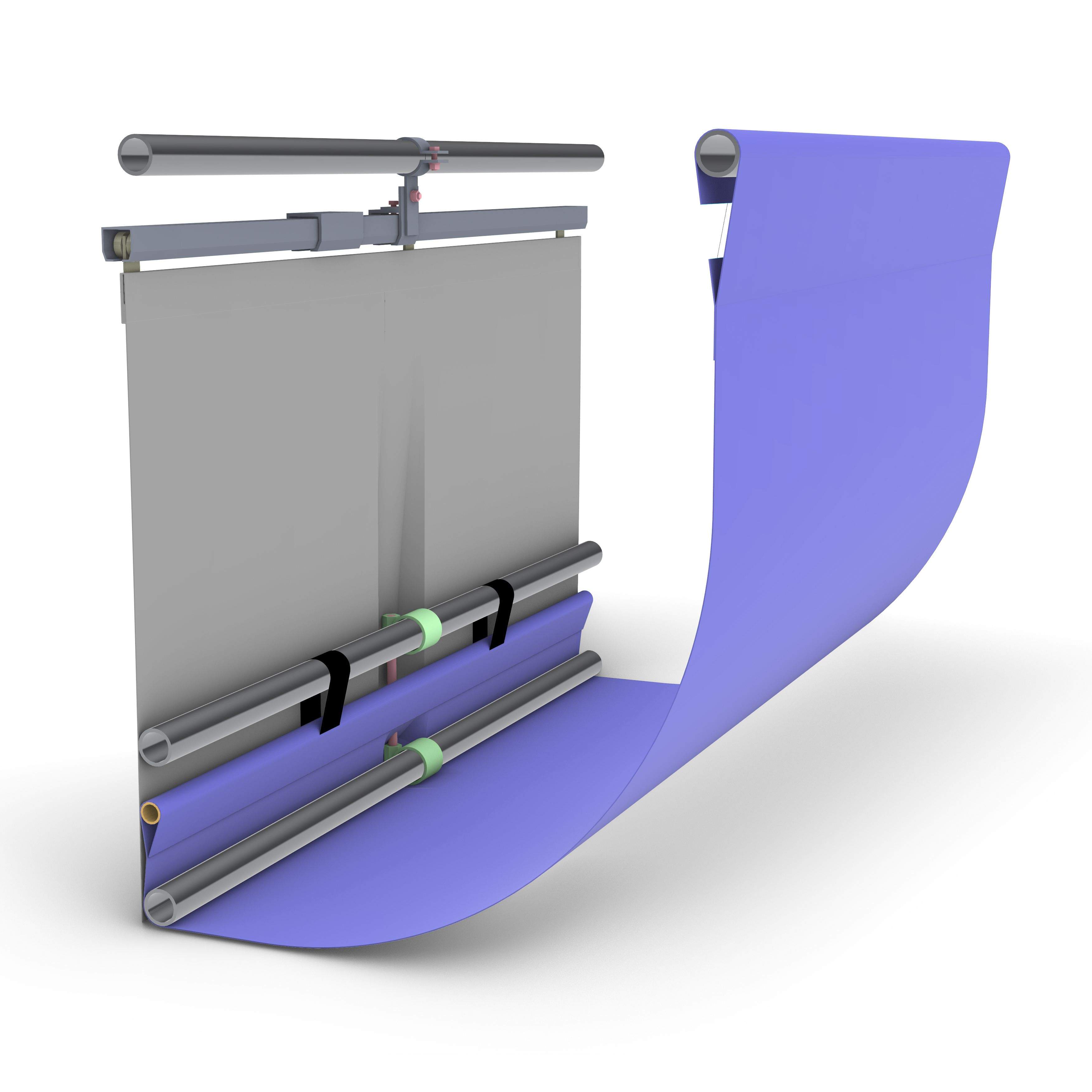

The Bourbaki Panorama in Lucerne houses one of the last remaining 360° cycloramas. To enhance the immersive experience of this monumental painting, a specialized optical apparatus shapes the incoming light. After 24 years, the apparatus—including sixteen textile sails, a central velum, and a large overhead baldachin—was renewed. The challenge: modernizing the system with state-of-the-art materials while drastically reducing weight due to structural constraints.

Details

The textile system consists of:

16 sails, each individually shaped and mounted on a tailored steel structure adapted to the building’s asymmetry

A velum covering the central ceiling to diffuse daylight

A large, visitor-facing baldachin suspended above the panorama

The building’s tilted geometry and the weight limits of the existing structure required bespoke engineering and detailing. Key requirements included low weight, flame retardancy (B1), UV stability, and selective opacity to support the lighting concept.

Specifications

Net area sails | 16 × 25 m² = 400 m² |

Net area velum | 620 m² |

Net area baldachin | 500 m² |

Baldachin diameter | 23.5 m |

Baldachin height | 8.4 m |

Date | 2013/2024 |

My role

I was responsible for the technical development and implementation of the textile components. This included evaluating the building survey, analyzing measurement data, and developing customized solutions in response to the structural asymmetries. I led the form-finding process, prepared detailed execution drawings as well as fabrication plans and cutting patterns for the large-scale baldachin. Additionally, I oversaw technical aspects of the project, coordinated the disassembly of the old system, contributed to the development of the assembly concept, and supported the on-site installation, including providing instructions to the assembly team. I also authored the technical project report and coordinated media communications.

My sketches

Results

The renewed apparatus seamlessly integrates into the historic space, significantly improving light diffusion and visual quality. The textile upgrade maintains fire safety and material durability while reducing structural load—ensuring both aesthetic and technical excellence for years to come.

Note

This project was completed during my time at Bieri Tenta AG, the company responsible for its execution. The insights and results presented here are based on my professional experience in the planning and realization of textile architecture as part of my role at Bieri Tenta AG.