Textile roof structures are rarely refurbished – more often, they are replaced entirely. Yet even membranes that were originally well-designed and properly installed can deteriorate after 30 to 40 years due to insufficient maintenance, water ingress, or visual degradation. Other common issues include damage from collisions, modifications, or natural wear and tear – particularly in temporary structures. In some cases, poor design choices such as non-adjustable membranes can also lead to early failure.

Preserving the existing substructure and anchorage points is often desired for sustainability and cost reasons – but this adds complexity. Two key challenges arise frequently in refurbishment projects:

1. Missing Documentation

When the original structure was designed and built by another company, detailed execution or fabrication drawings are often unavailable. These must be reconstructed through reverse engineering – a demanding task, especially for doubly curved membranes or intricate edge geometries.

Case Study 1

A fabric envelope over 40 years old had to be replaced due to severe leaks. Since the covered space was still used as an event venue and repair was no longer an option, the entire membrane needed renewal. Lacking any documentation, the existing structure was captured via 3D scan, and a new membrane was designed accordingly. In hindsight, regular maintenance could likely have extended its service life significantly.

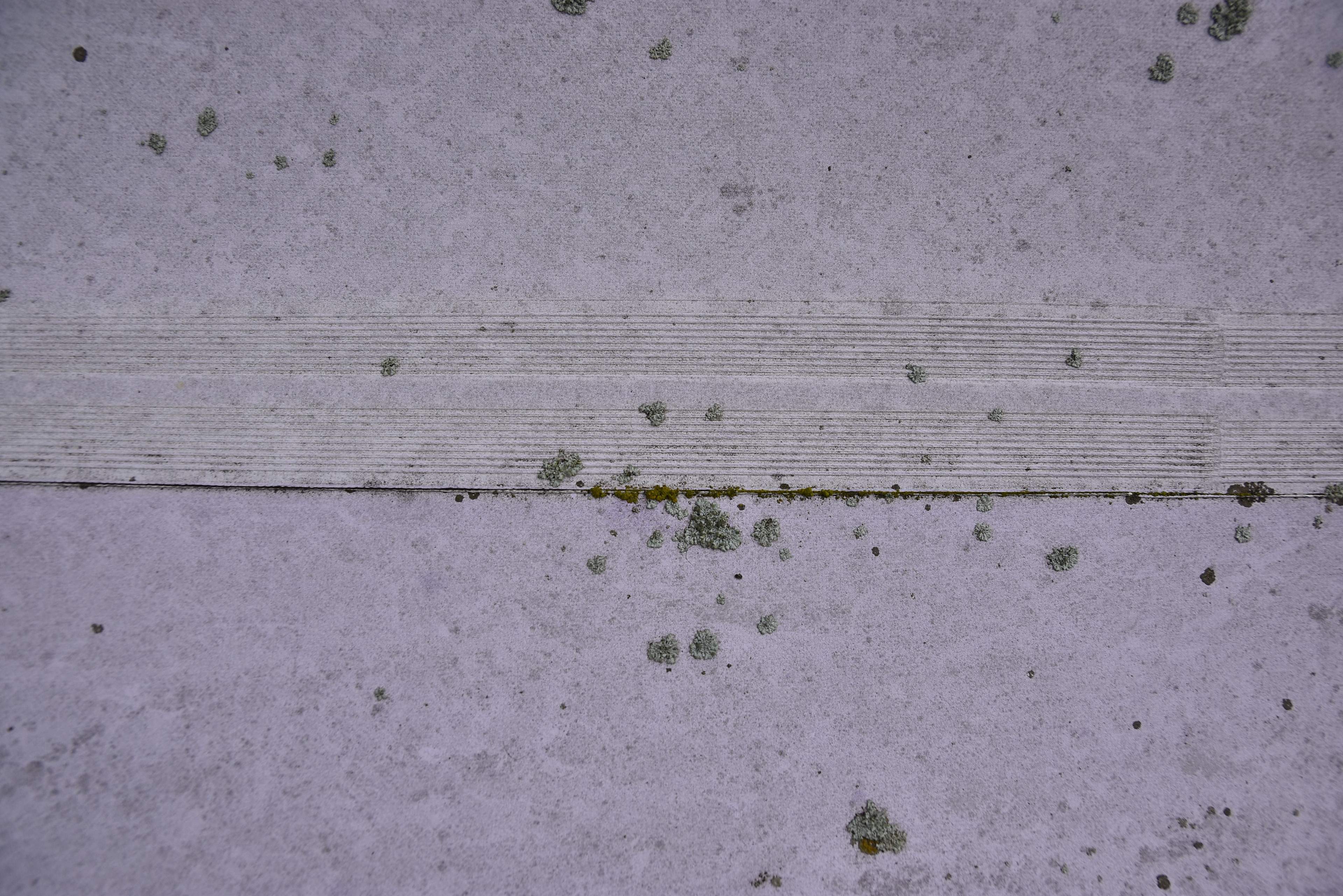

Worn coating and lichen growth on a PVC/PES membrane.

2. Missing Structural Verification

Many older projects lack verified structural analysis. Early design approaches often relied on outdated load assumptions or undocumented engineering judgement – especially for smaller structures. Modern safety standards require a reassessment, which is difficult without calculations, reports, or material data.

Case Study 2

A temporary roof has been erected and dismantled annually for over 14 years – without visible damage. However, a change in use required one of six columns to be relocated. This altered the roof geometry to such an extent that a new membrane and new anchoring points had to be designed. Plans existed – but no structural report. A new assessment was supported by CFD wind analysis to evaluate wind effects more accurately.

Column relocation creates more space for a green façade.

Case Study 3

A sunshade over 20 years old showed flutter damage and tearing due to loss of membrane tension. The design did not allow for re-tensioning, and the material condition made repair impossible. No documentation or calculations were available. A preliminary design study was carried out, aiming to reuse the supporting structure with defined reinforcements. The new membrane is now tensionable and made of higher-quality material.

Omitting tensioning details may reduce initial costs, but leads to problems in the long term.

A slack membrane is prone to flutter damage.

Key Takeaway: Expertise Is Essential

Refurbishing membrane structures is often marked by uncertainty and missing information. When the existing structure is to be preserved, experience and thorough preliminary investigations become essential. This includes site inspections, exploratory probes if needed, and a robust structural assessment based on current standards.

If you find yourself in such a situation – or want to be prepared – it's wise to consult with a specialist in membrane architecture. Experts in this field are rare, so pay attention to solid references. Long-established companies are often a good choice. If they don’t have in-house specialists, they typically work with reliable networks.

Avoiding the Need for Refurbishment – Three Simple Recommendations

Not every refurbishment can be avoided – but many can. Consider the following best practices during the design and operational phases:

Use high-quality technical textiles designed specifically for architectural applications.

Ensure the engineering is carried out by qualified and experienced professionals.

Perform regular maintenance – even for temporary structures.

These measures can prevent a significant number of avoidable damages and complex refurbishments.

This article is based on hands-on experience from my current role at Bieri Tenta AG, where I have been involved in the planning, refurbishment, and execution of membrane structures for several years.

Interested in a collaboration on refurbishment projects or research related to membrane structures? Feel free to get in touch.