Introduction

Over the past weeks, I have published a five-part series of thought experiments on textile architecture on LinkedIn – under the hashtag #textilemindshift.

Each post was framed as an open question – intended not to deliver ready-made answers, but to spark new perspectives on ultra-lightweight construction and to invite reflection on weight, mobility, precision, material intelligence, and cultural change in architecture.

This concluding article brings these threads together:

It summarises the five thought experiments in a concise format, adds a real-world case study, and demonstrates that these ideas are not just visions – but can be realised today with existing technologies, materials, and processes.

Links to the original LinkedIn posts are embedded so you can follow the discussions and responses in context.

This Series Was Never About Ready Answers

It was never meant to promote a product or present a finished technical solution.

It was about asking questions – deliberately open ones – that leave space.

Space for your own imagination.

Space for what could be possible if we dare.

Space for the thought: If we can imagine it, we can find a way to make it happen.

The five thought experiments in this series are exactly that – mental exercises designed to inspire, to encourage new mental images, to open up possibilities, and perhaps even to spark the desire to co-create.

Five Thought Experiments – Five Impulses

🧠 #1 – Rethinking the Envelope

What if we erased the line between roof and façade? A modular, highly parametric textile system – light in weight and in planning – versatile enough for both temporary and permanent architecture. → Read the original post

🧠 #2 – Architecture in a Container

What if a complete façade – substructure, membrane, and details – could fit into a single shipping container? Shipped anywhere, quickly assembled, climate-friendly. Architecture conceived as mobile and scalable. → Read the original post

🧠 #3 – Bespoke, Not Off-the-Rack

What if textile façades were tailored like bespoke suits – precisely digital-modelled but manufactured with industrial efficiency? No rigid BIM workflows, but a co-design process with a digital twin that integrates real-time adjustments and drastically shortens fabrication time. → Read the original post

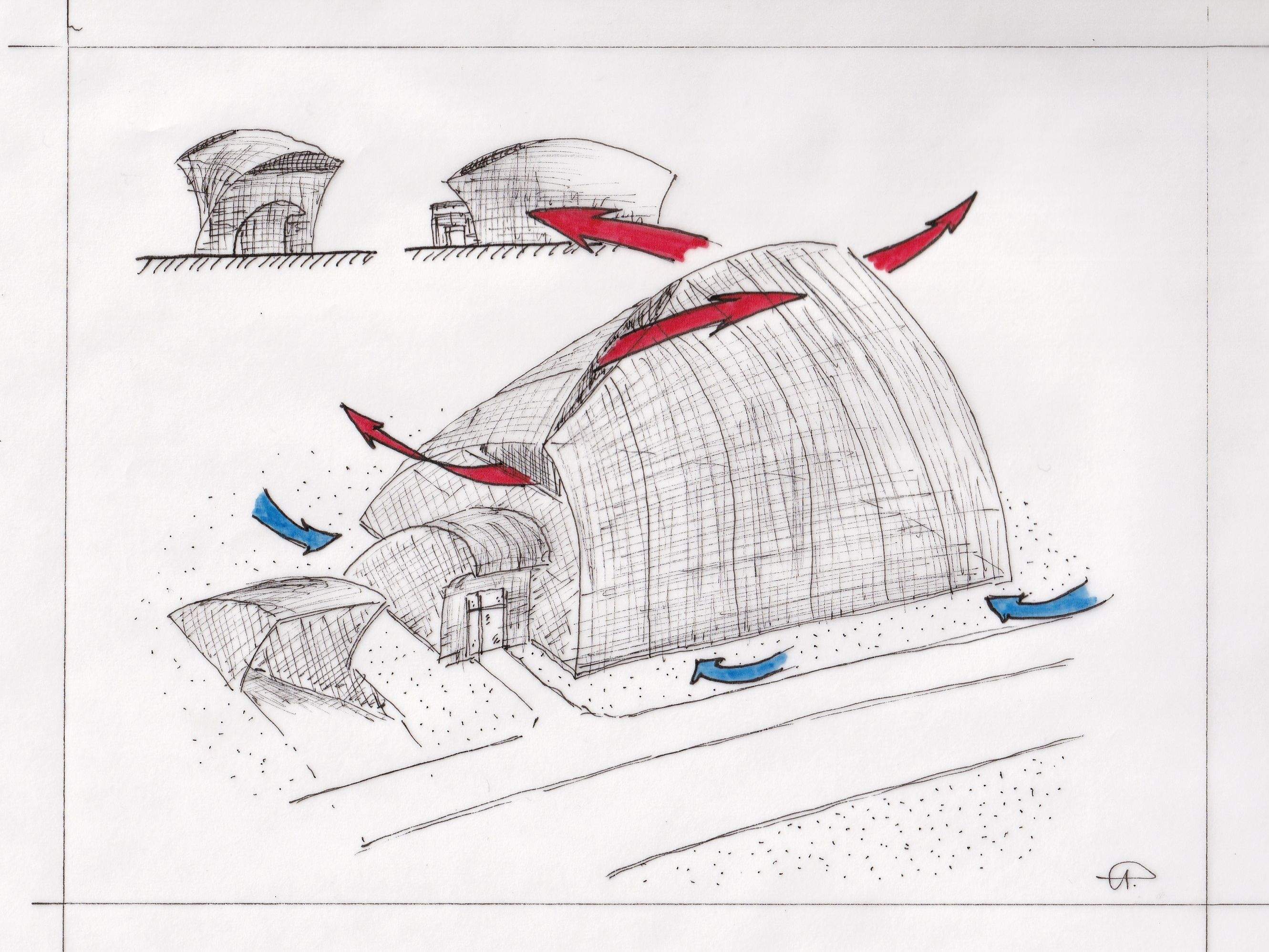

🧠 #4 – The Breathing Skin

What if a façade could think, feel, and react – without building controls? Bionically inspired, multi-layered envelopes that regulate heat, circulate air, and modulate light – purely material-driven, like the skin of a living organism. → Read the original post

🧠 #5 – Architecture from the Logic of Materials

What if ultra-lightweight construction became the norm? An architecture that does not impose form, but allows it to emerge from the material’s performance – honest, functional, poetic. → Read the original post

Case Study – Gelateria Mulegns

The Gelateria Mulegns in the Swiss canton of Graubünden proves that textile lightweight visions are already a reality.

This visitor centre for the White Tower combines reclaimed timber from an open-air theatre with a highly translucent membrane made from fluorocarbon-coated glass fabric.

Lightness: Only 4.78 kg/m² for a total area of 272 m².

Speed: Three prefabricated membrane parts, hidden aluminium profiles, and rapid on-site installation.

Aesthetics: Maximum daylight utilisation with a clear view of the timber structure by day; a lantern-like glow at night.

This project shows that textile architecture is not only visionary – but also ecological, efficient, and architecturally refined. With existing know-how. Today. → Read the original post

Conclusion – From Thought Experiment to Action Field

Each of these five thought experiments touches on a core aspect of textile architecture: weight, mobility, precision, material intelligence, and cultural change. Together, they paint a picture of a building method that is technically mature, aesthetically diverse, and ecologically sound – yet still too rarely applied consistently.

The message is clear: This is not a distant utopia. This is something that can be built – today – with existing technologies, material expertise, and proven planning and assembly methods.

What’s missing is not the technology, but the systematic, integrated solution. And the willingness to embrace the consequences that ultra-lightweight construction entails – in design and in cultural mindset.

Outlook – The Invitation

The demand for ecological and economically viable solutions is there.

The technologies for planning, fabrication, assembly, and operation are there.

The building physics knowledge is there.

Only one thing is missing: people who are ready to be inspired – architects, engineers, clients, and planners – willing to take these ideas seriously and work together to establish a new, ultra-lightweight way of building.

Do you count yourself among them?

I’m ready.

This series and article are based on my work and observations at Bieri Tenta AG, where I have been deeply involved in the planning, refurbishment, and realisation of textile structures for several years. They were created from my own initiative and personal interest and reflect solely my own perspective.