Ultralight Building Envelope for the Mulegns Visitor Centre

Project overview

The Gelateria Mulegns serves as a visitor centre for the “White Tower” in Mulegns — the tallest 3D-printed building in the world. Designed as a lightweight timber structure made from reused wood of the Lantsch/Lenz open-air theatre, the project required an equally lightweight and expressive building envelope. The membrane solution, developed by Bieri Tenta AG, complements the innovative architecture with translucency, speed of installation, and material efficiency.

Details

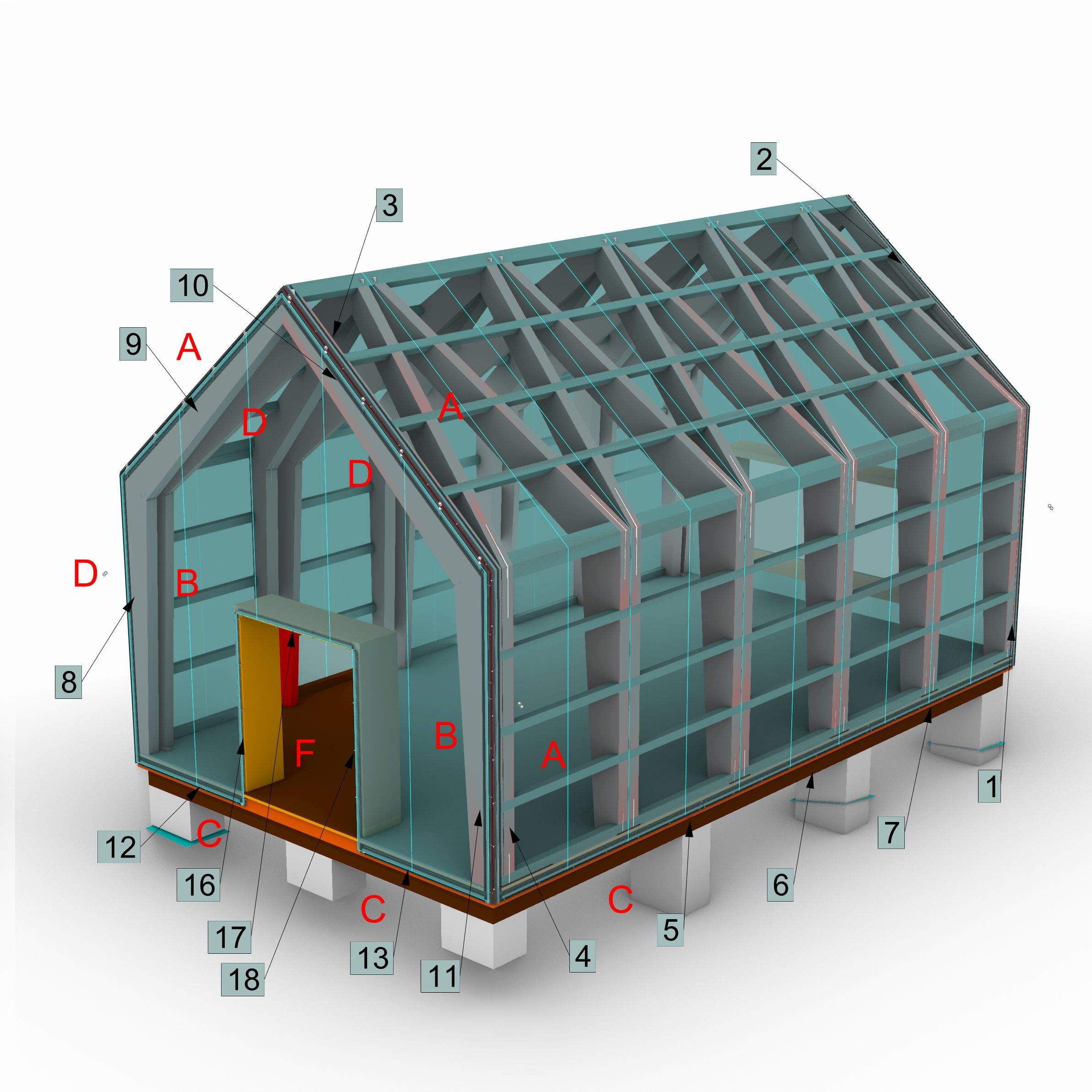

To preserve the visual impact of the tilted timber frame structure while ensuring functional enclosure, a translucent and partially transparent membrane envelope was chosen. The material allows daylight to penetrate the space while creating a glowing lantern effect at night. From outside, the timber structure remains visible; from inside, privacy is maintained without creating a closed-off showroom feeling.

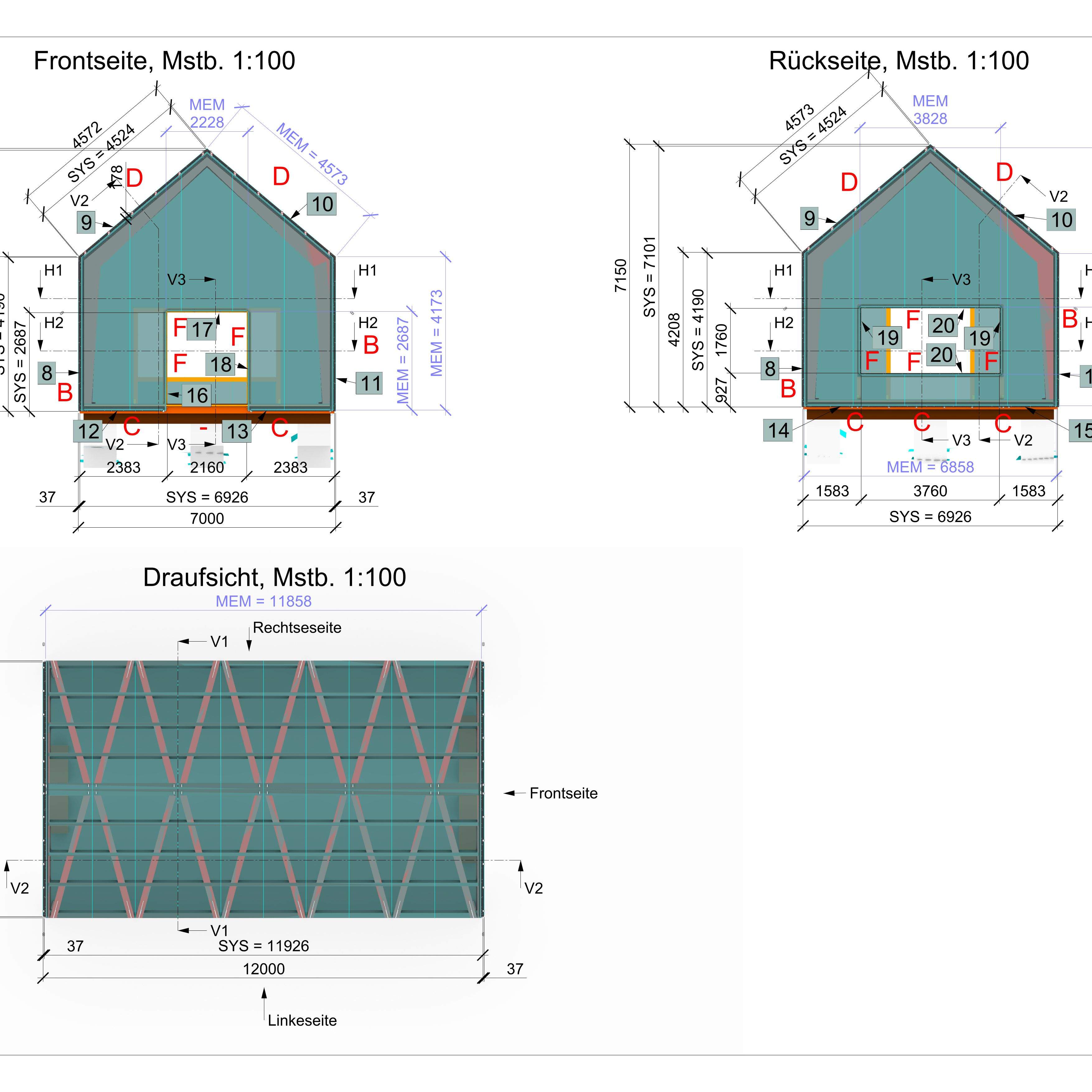

The membrane surface is composed of three prefabricated parts: a front element with door cut-out, a rear section with window opening, and a main piece covering the roof and side façades. All membrane parts are fixed with concealed aluminium profiles. The connection to the timber structure is achieved via a preassembled steel tension frame.

Specifications

Dimension | 12.00 ⋅ 7.00 ⋅ 7.15 m (l ⋅ w ⋅ h) |

Area | 272 m2 |

Membrane weight | 0.85 kg/m2 |

Weight of the entire membrane system | 4.75 kg/m2 |

Date | 2025 |

Status of the project | Completed |

Tools used | RFEM, Rhino 3D, Grasshopper, Excel |

My role

From the initial feasibility discussion to the final installation, I was responsible for the comprehensive development and implementation of the textile envelope. My work began with early consultations on the architectural and technical possibilities of textile cladding, followed by preparing the basis for a detailed offer. I coordinated closely with the timber construction team to ensure seamless integration between the wooden structure and the membrane system.

Building on a pre-existing concept, I adapted and developed a custom façade system tailored to the specific geometry and functional requirements of this project. I produced detailed system drawings and section cuts, conducted the structural analysis of the textile façade, and calculated the anchoring forces to be transferred to the timber structure.

In the implementation phase, I handled both execution and fabrication planning of the entire façade system. I instructed the production team on the specific requirements of the membrane components and guided the on-site installation. Throughout the process, I remained actively involved in project supervision to ensure that design intent, structural performance, and visual quality were consistently upheld.

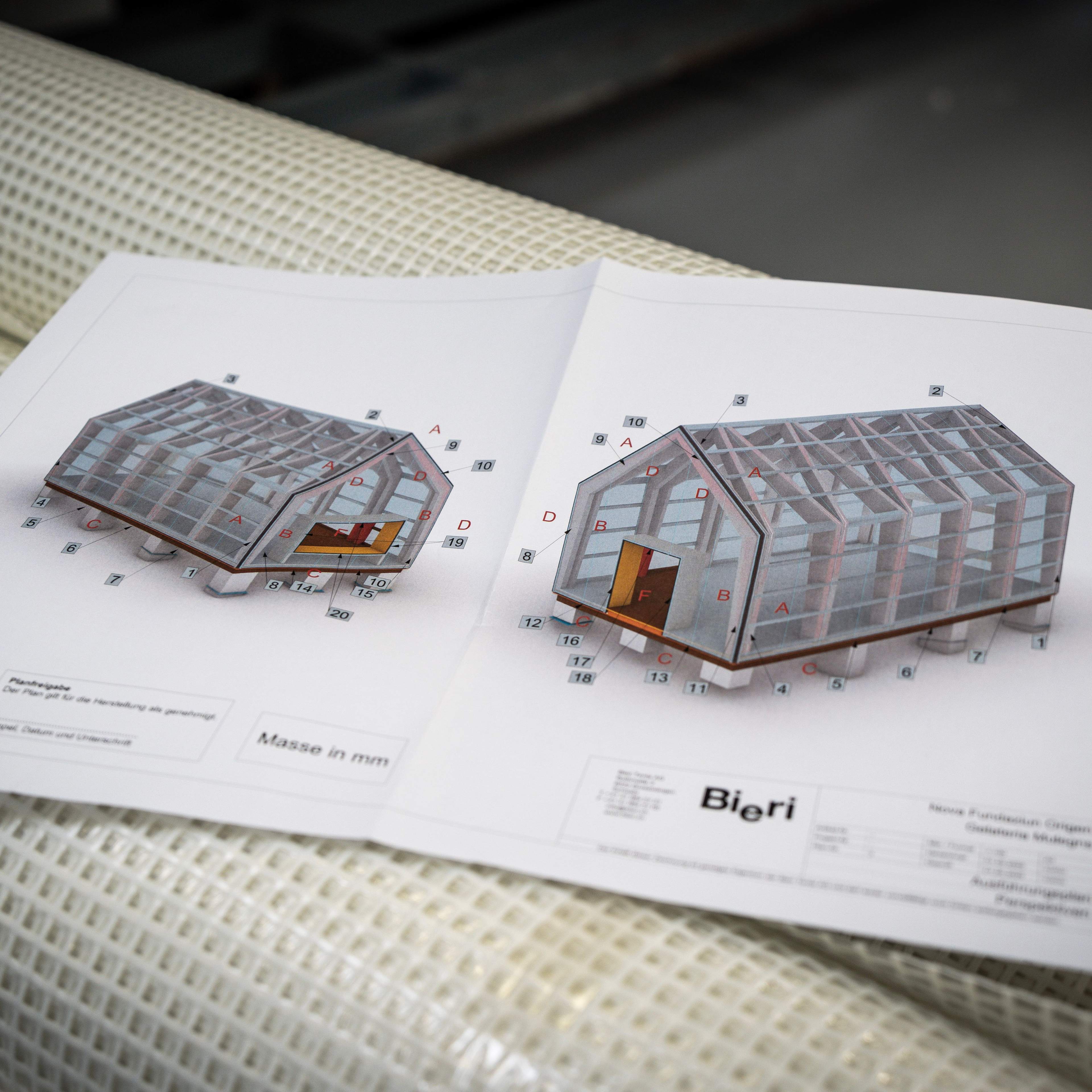

My sketches

Results

The resulting structure demonstrates the potential of membrane architecture in creating ultra-light, fast-to-install, and aesthetically compelling building envelopes. By embracing the specific characteristics of technical textiles, this project achieves a unique spatial quality and architectural expression that conventional solid construction would struggle to replicate. The blend of timber and membrane materials not only enhances sustainability but also offers a forward-looking architectural language.

Note

This project was completed during my time at Bieri Tenta AG, the company responsible for its execution. The insights and results presented here are based on my professional experience in the planning and realization of textile architecture as part of my role at Bieri Tenta AG.