Insights from practice – by an expert in textile architecture working at the interface of design, engineering, and fabrication

Introduction

In textile architecture, many decisions are justified with so-called “experience values”: How wide should a seam be? Which welding technique is most appropriate? What temperature sensitivity can be expected? But what exactly are these “experience values”? Are they documented, repeatable, and comparable? Or are they assumptions dressed as facts?

As someone working at the intersection of architecture, engineering, and textile fabrication, I’ve come to realise that real experience needs to be backed by real data. That’s where material testing comes into play – not just the highly complex ones like biaxial testing, but also simpler tests that can already reveal a surprising amount of insight.

In this article, I’ll highlight why basic uniaxial tensile tests are often underestimated, why every textile fabrication workshop should have access to a tensile testing machine, and how test results can guide both technical and economic decisions in membrane construction.

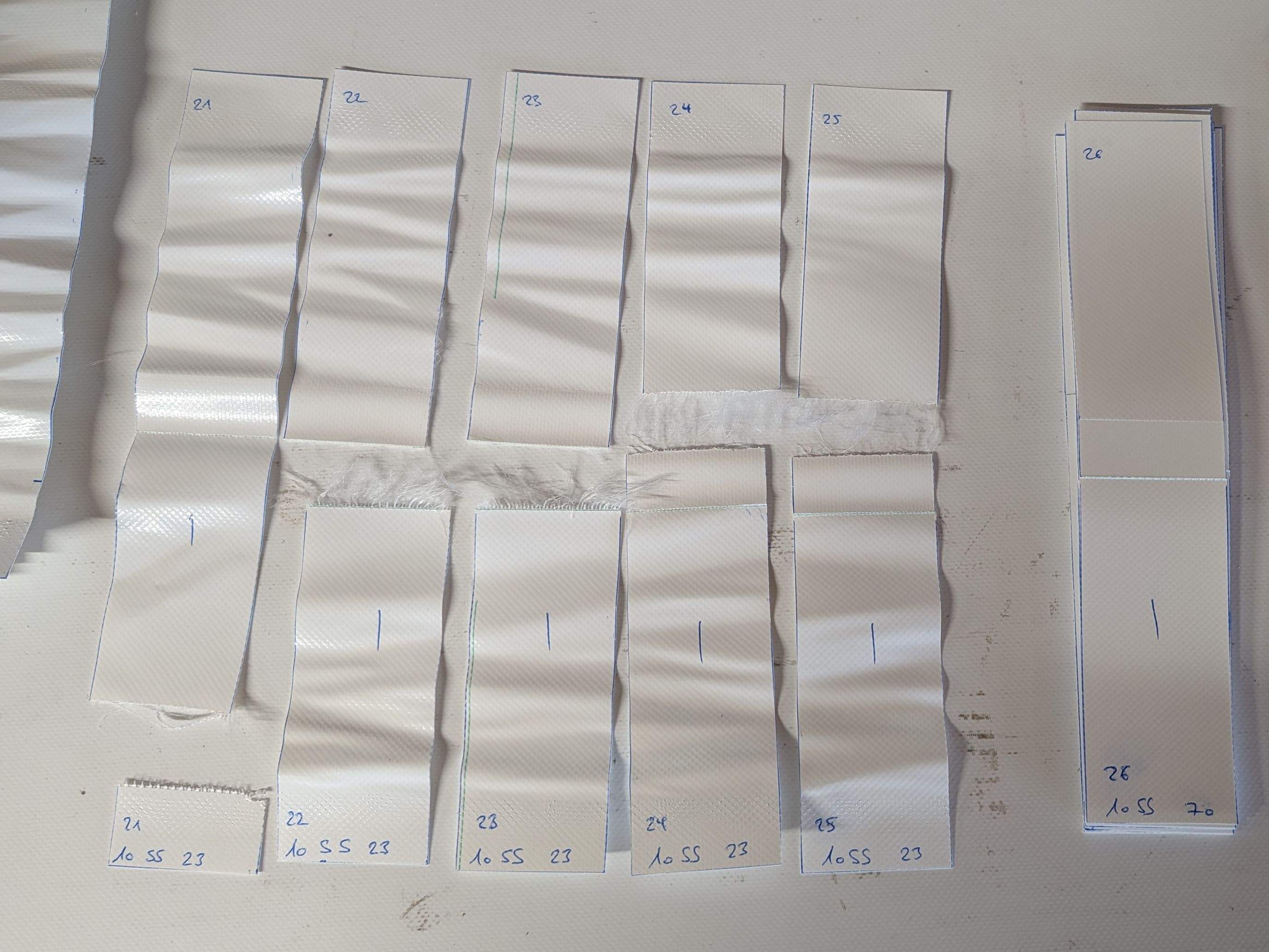

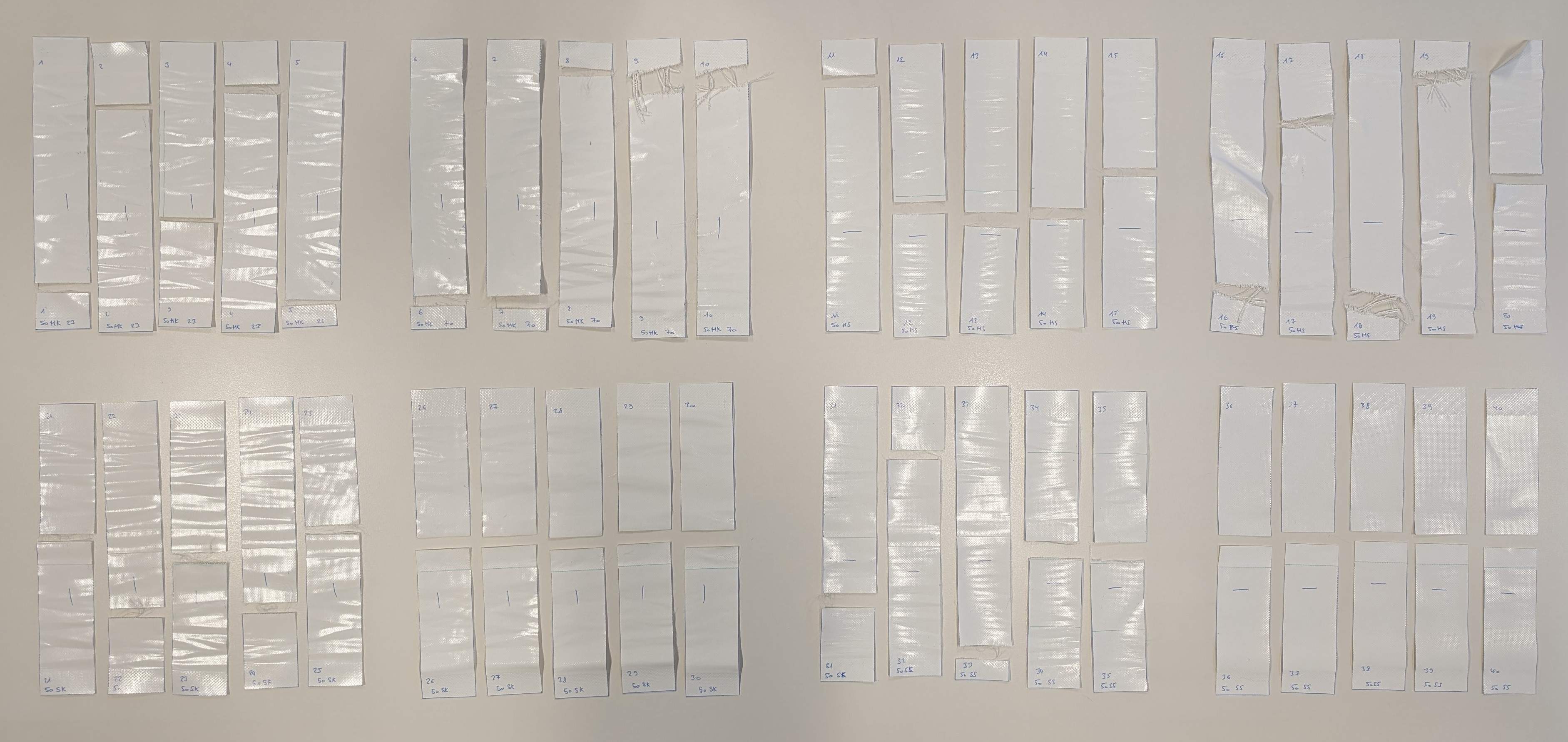

Important information about the materials can already be obtained during the preparation of the test specimens. The fabric orientation and the angle between the warp and weft threads are important indicators in this regard.

Order is essential! A test batch can consist of 20 or 40 test strips. To avoid confusion during testing and to be able to trace how the tested samples are classified afterwards, a unique sample designation (coding) is necessary.

Types of Material Tests and Their Insights

1. Uniaxial tensile strength of the base material (at 23 °C)

This is the most basic test: How much tensile force can the raw membrane material withstand before it fails?

Most manufacturers include this value in their technical data sheets. However, verifying it in-house allows you to check for homogeneity across batches or rolls and to compare different materials under consistent conditions.

If a structure encounters unexpected durability issues, testing the base material is a good first diagnostic step.

2. Uniaxial tensile strength of the base material (at 70 °C)

While 23 °C is standard, real-world applications often face higher ambient temperatures – especially for dark-coloured membranes or structures in hot climates.

If your testing equipment includes a climate chamber, it’s highly recommended to test the same membrane at 70 °C.

This test is not typically included in technical data sheets, but it provides valuable insights into the thermal sensitivity of the material and its long-term reliability.

3. Uniaxial tensile strength of seams and welded connections (at 23 °C)

This test evaluates the strength of joints – stitched or welded – under standard conditions.

It is often required by design codes (e.g. EN 1991, EN 13782) and serves both a quality assurance and economic function:

Does the connection method meet standards?

Can the seam width be reduced safely, saving material and labour time?

Do test results align with the performance of the base material?

4. Uniaxial tensile strength of connections (at 70 °C)

Testing joints at elevated temperatures is crucial in certain contexts. For example, EN 13782 (which governs temporary structures) explicitly requires such testing.

Comparing the joint performance at 23 °C and 70 °C – and in relation to the base material – helps identify critical weak points under thermal stress, which is especially relevant for coloured membranes.

5. Testing Keder assemblies

Keder (edge profiles) are essential in tent and membrane construction, and their strength should not be taken for granted.

Some standards, like DIN 18204-1, require tensile testing of keder assemblies, including both prefabricated keder and those fabricated from the membrane material itself.

Weak keder or improper combinations with aluminium profiles can result in slippage, which can cause serious installation or performance issues. A simple pull test can prevent this.

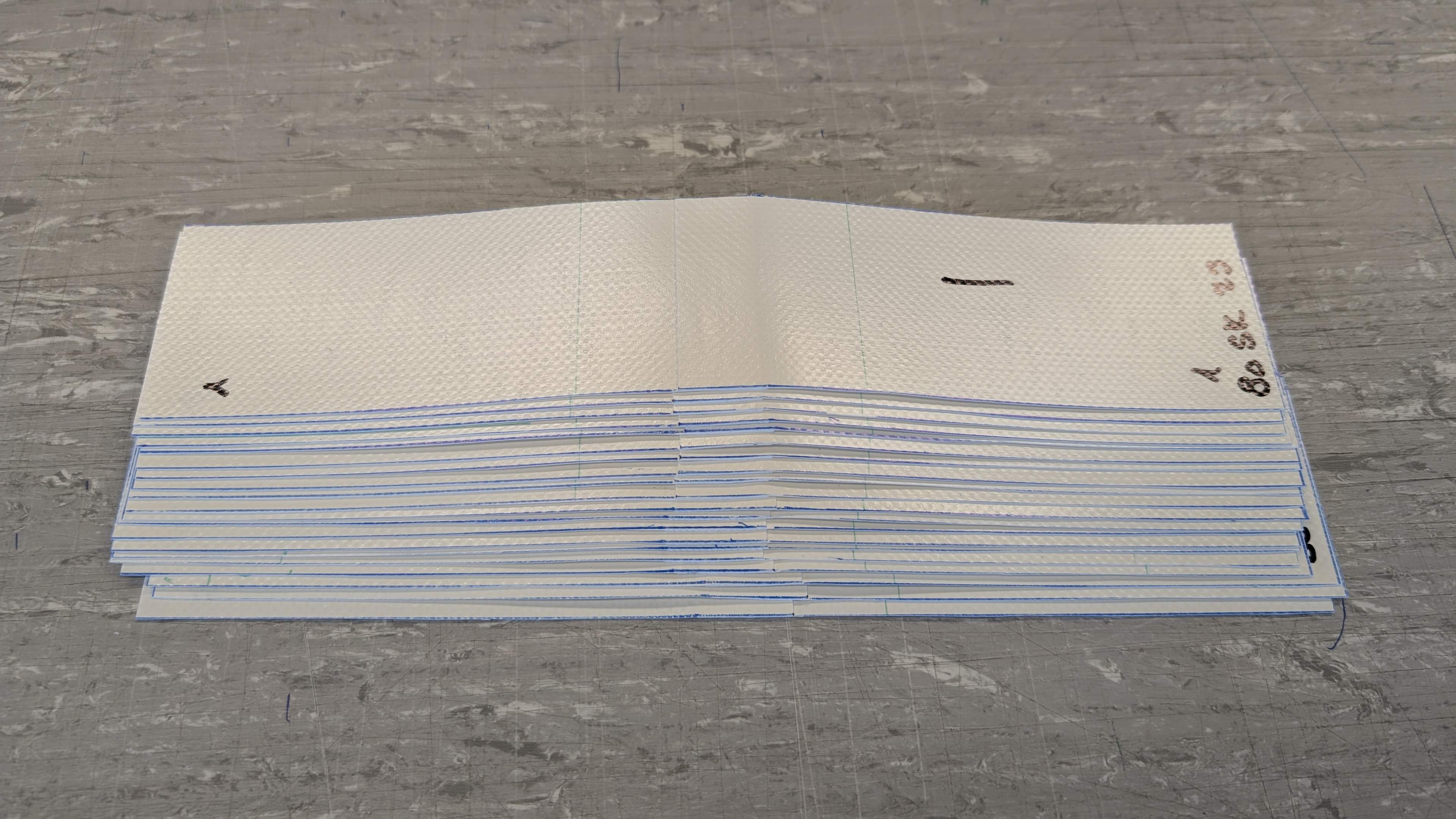

It doesn't always have to be the latest and most modern: a reliable testing machine can also be used effectively and meaningfully in an improvised workplace.

Whether old or new testing machines: a climate chamber not only allows more measurements to be carried out, but also provides significantly more information about materials and seam connections.

Why You Should Always Use Statistical Evaluation

Measuring force and extension is only the start. Statistics help transform raw test data into meaningful engineering insight:

Mean value: Offers an average, but is not suitable for design.

5% fractile: This lower-bound value is used to define safe characteristic values for structural design.

Standard deviation: Indicates the scatter of test results. High deviations suggest inhomogeneity in material or inconsistency in welding or stitching.

Coefficient of variation: Useful for comparing scatter across different material types or connection methods.

Visual Inspection Matters, Too

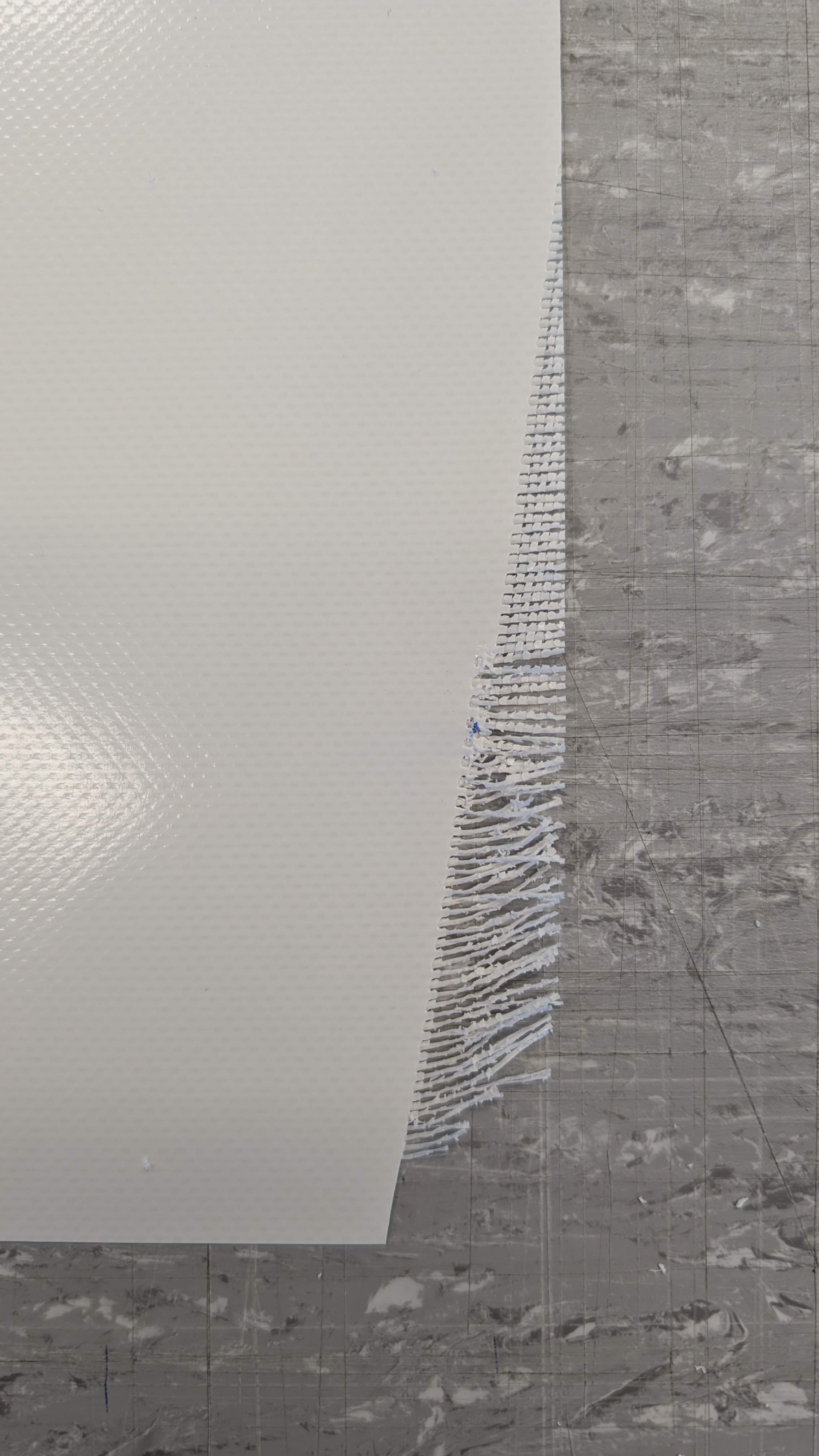

Don’t stop at numbers. Examining the failure mode of the material or connection gives crucial insight:

Cohesive failure (within the membrane)

Adhesive failure (between layers or at the joint)

Mixed failure

Understanding these patterns helps assess whether the failure is caused by poor bonding, inappropriate materials, or machine calibration issues.

Conclusion

Material testing in textile construction is more than a regulatory checkbox. Even the simple strip tensile test – when executed properly and evaluated with care – can tell us a lot about material quality, fabrication consistency, design safety, and even cost optimisation.

In my work at Bieri Tenta AG, I’ve had the chance to explore this topic in-depth and see first-hand how much value even modest testing equipment can provide – especially when paired with technical curiosity and a structured approach.

If you are involved in designing, engineering, or fabricating textile structures:

Don't just trust datasheets.

Don't rely on assumptions

Ask for test reports – or better yet, run your own tests.

Because in textile architecture, knowledge truly is tensile strength.